Main scope of application:

- Food industry;

- Chemical industry;

- Medicine;

- Architecture and construction;

- Aviation and automotive industry.

PROCESS OF MANUFACTURING STAINLESS STEEL PRODUCTS

The production of stainless steel products, including custom-made ones, can be carried out using the following metalworking processes:

- Cutting . Accuracy and compliance with all specified parameters is ensured by CNC equipment. Processing field size 3000x1500 mm;

- Flexible . Bending is necessary in cases where, without welding, it is necessary to produce products with angles from 30 to 180 degrees, or the workpieces have complex contours;

- Welding . As a rule, welding work is necessary when creating complex parts and structures. The type of welding is selected depending on the specific purposes and thickness of the material;

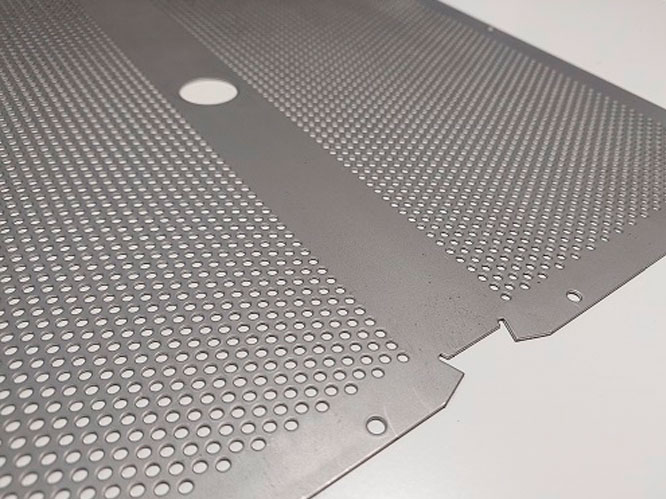

- Perforation (coordinate punching) is acceptable with almost all types of stainless steel, regardless of composition.

TYPES AND TYPES OF STAINLESS STEEL PRODUCTS PRODUCED BY US

- Fencing of any type, from street to those that will be used exclusively indoors;

- Tanks and other containers for various purposes;

- Cabinets used both indoors and outdoors;

- Racks, tables and shelves for both industrial, medical, industrial and household purposes;

- Trade and exhibition equipment for various purposes (showcases, stands, holders, bumpers, tanks, etc.);

- Metal structures and building structures, both compact and large in size;

- Household and decorative elements used both indoors and in direct contact with the environment (sinks, bathtubs, sinks, tables and countertops, furniture);

- Parts for various purposes, both small sizes of any level of complexity (including those with complex contours) and large ones;

- Decorative elements for interior and exterior made of stainless steel with shaped laser cutting;

- Partitions, frames, frames, gratings, railings, handrails;

- Facing elements;

- Screens, boxes, cases, boxes, panels;

- Benches, benches, trash cans, stairs;

- Brackets, corners, parts;

- Industrial and technological equipment for food and chemical production;