LLC Production Complex «Svet Shakhtyora»

production of metal products

metal structures, machine-building products, parts, furniture

works of LLC Production Complex "Svet Shakhtyora"

100 +

experienced and responsible persons work at the enterprise

5000 + ą╝2

total area of ŌĆŗŌĆŗproduction buildings and structures

Enterprise activity

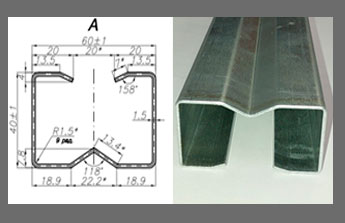

The company LLC Production Complex «Svet Shakhtyora» is focused on the production of metal products. Manufacture of metal structures for such areas as construction, trade, refrigeration equipment, mechanical engineering, as well as furniture in the "Loft" style both for industrial premises and for home.

We offer a range of sheet metal processing services: laser cutting, bending, sheet metal perforation, cold stamping, welding and metalwork, manufacturing of custom parts and metal structures, powder painting.

Our designers undertake the most complex technical tasks, a full cycle of design, development and manufacture of metal products on CNC machines. Cutting is carried out on equipment from European manufacturers. Shipment is carried out both from the manufacturer's warehouse and with delivery to the Customer's warehouse.

The available machine park and equipment allows us to organize production and technological processes to perform all the main technological operations according to the classifier 1 85 151 from the workpiece to the assembled unit, assembly, painting, packaging in containers.

The qualification of the personnel guarantees the purity of processing and the quality of the product in full compliance with the requirements laid down in the design documentation.

All work is carried out strictly within the contractual time frame. Shipment is carried out both from the manufacturer's warehouse and with delivery to the Customer's warehouse.

TRUMPF coordinate punching machines and professional laser cutting complexes ARAMIS with hermozones allow for high precision and cutting quality with minimal waste of metal with a thickness of 0.5-14.0 mm with a processing range of 3000 × 1500 mm, as well as with the possibility of cutting galvanized and non-ferrous metals up to 6 mm

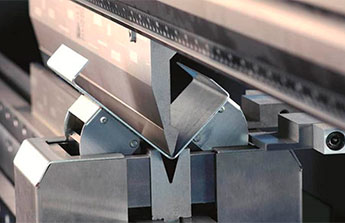

Bending of parts is carried out on German equipment TRUMABEND 850S and V130 (length up to 3000 mm, thickness up to 6.0-12 mm.), which allows you to accurately and quickly give the workpiece the necessary form, according to KD.

Welding is carried out using TESLA semi-automatic machines

Powder painting provides a high quality coating and also maintains excellent physical and chemical characteristics.

Also, the production facilities are equipped with relevant modern equipment, such as an automatic line for cross-cutting metal, PILOUS band saw machines, vertical drilling machines, stamping presses, guillotine and other equipment.

The entire production cycle is closed near production. Engineers and managers are closely related to production and have the opportunity to constantly monitor and improve the manufacturing process.

With the quality of our products and individual approach to each client, we have earned the trust of both small firms and world-renowned companies.