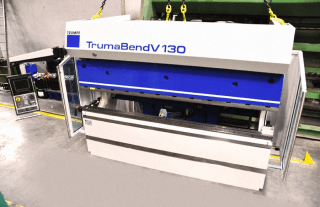

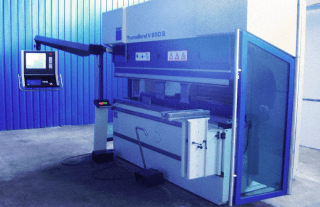

Bending of parts is carried out on German equipment TRUMABEND 850S and V130 (length up to 3000 mm, thickness up to 6.0-12 mm.), which allows you to accurately and quickly give the workpiece the necessary form, according to KD.

Welding is carried out using TESLA semi-automatic machines

Powder painting provides a high quality coating and also maintains excellent physical and chemical characteristics.

Also, the production facilities are equipped with relevant modern equipment, such as an automatic line for cross-cutting metal, PILOUS band saw machines, vertical drilling machines, stamping presses, guillotine and other equipment.

The entire production cycle is closed near production. Engineers and managers are closely related to production and have the opportunity to constantly monitor and improve the manufacturing process.

With the quality of our products and individual approach to each client, we have earned the trust of both small firms and world-renowned companies.

Press brake Trumpf TrumaBend V130

- гибка деталей любой сложности (толщина металла от 0,5 до 6,0 мм, обрабатываемая длина листа: 3060 мм)

- компенсация прогиба (ЧПУ бомбардировки )

- усилие – 130 тн

- стабильная рамная конструкция

- Электрогидравлический привод нижнего хода

- современная система блочной гидравлики

- компенсация прогиба (ЧПУ Бомбирование)

- 4-х осевой задний упор (X, R, Z1, Z2)

- Инструментальная зажимная система Wila NSCL (Hydr.)

Press brake Trumpf TrumaBend V850S

- bending a part of any complexity (thickness 0.5 - 6.0 mm; maximum bending width 2500 mm)

- minimum shelf depending on the thickness of the metal from 7.0 (thickness 1.0 mm), to 18.0 mm (thickness of the metal 3.0 mm))

- the design of the press allows for complex bends (the upper executive tool - the assembly punch and the matrix - the lower tool are similar, the tool radius is 1.0 mm, bombing),

- accuracy of work from 0.05 to 0.1 mm.

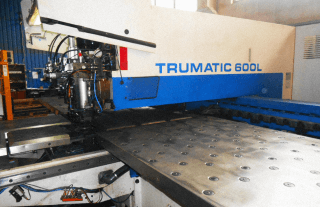

Combined laser and coordinate punching press TRUMATIC 600L

- cutting area size (X x Y) without repositioning, 2580 x 1280 mm

- high speed of workpiece positioning

- maximum workpiece thickness, mm 8.0

- maximum processing force, KN 220

- maximum workpiece weight, kg 200

Combined laser and coordinate punching press TRUMATIC 1000R

- for cutting without jumpers, for bending flanges,

- roller tools for creasing and shaping

- puffing (blinds, hood, edging)

- thread cutting, rolling of stiffeners

- Reliability of operation ensured by the use of a maintenance-free electro-hydraulic drive of the slider

- effective marking with a special and marking tool, which is visible through the paint

- convenient and quick removal of parts through an automatic hatch

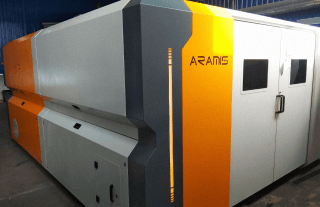

Laser complex AFX-2000 ARAMIS

- TREATMENT field size: (3000x1500) mm as max

- Processed materials: steel, including stainless steel, aluminum, copper, copper and aluminum alloys, titanium, graphite, etc.

- XY re-positioning accuracy in area: ±0.01 mm

- Max processed metal thickness: 14mm black steel, 10mm stainless in bone and 6mm stainless in nitrogen, aluminum, copper and other non-ferrous metals.

- Max SPEED of moving the laser head: 120m/min

- cutting speed: from 0.2 to 35 m/min (depending on the material being processed, its thickness and the complexity of manufacturing parts)

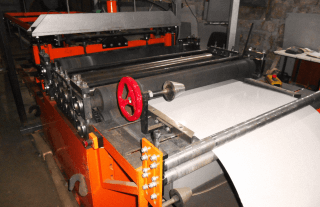

Metal cutting line APPR9U

- workpiece thickness - 0.3 mm-2.0 mm

- Cutting materials: steel, galvanized steel, polymer, aluminum

COMPOUND

1. Electric unwinder NO-RAD 10 tons 1 piece

2. Input device with guides 1 pc.

3. Lamination station (for film) 1 pc.

4. Extended rubber-coated shafts 2 pairs

5. Longitudinal cutting unit

6. Cross cutting (hydraulic guillotine) 1 pc.

7. Hydraulic system 1 piece

8. Reception table (stacker) 1 piece

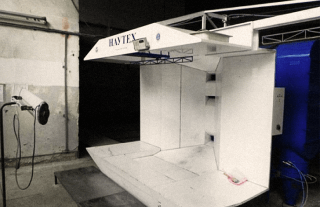

Painting Booth NAUTECH

- electric polymerization furnace, dead-end, with 3 upper transport crossbars with dimensions of the furnace working space: length - 3.0 m, height - 2.1 m, width - 1.2 m.

- The chamber is equipped with an additional shutter for painting the part from the opposite side.

- The efficiency of the aspiration system is 99.8%, the return of paint to the cycle is 98%.

- Fixed 1.8% powder paint waste (dust, fine impurities, small debris, etc.) collected on fine filters must be disposed of as solid waste.

- Camera power consumption: 4.1 kW