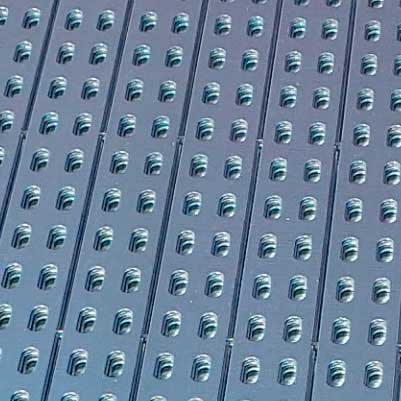

Sheet metal perforation

Coordinate punching of sheet metal according to drawings

The company Production Complex "Svet Shakhtyora" LLC carries out coordinate punching work for sheet blanks made of ferrous, galvanized, stainless steel or non-ferrous metals.

Metal perforation is a technological process of punching through metal sheets and obtaining a given number of holes of the required shape and size with the required coordinates. All sheet metal perforation parameters are controlled by CNC equipment. TRUMPF's high-precision punching presses provide a specified hole pattern and a fixed center-to-center spacing with impeccable reliability.

TRUMPF jig punching machines allow you to obtain high precision and cutting quality with minimal metal waste with a processing range of 3000×1500 mm.

Advantages of metal perforation on coordinate-punching presses

- High speed of operation - a coordinate punching press allows you to very quickly perforate metal sheets. Which, in turn, has a positive effect on the cost of products. Especially in the manufacture of serial and mass-produced parts.

- Processing of various metals : low-carbon steel, stainless steel, aluminum, etc. The improvement in the quality of non-ferrous metals is especially noticeable when compared with laser cutting.

- There are no thermally affected zones —the edge of the metal being processed does not overheat and does not change its mechanical properties.

- Accuracy and repeatability – CNC punching machines allow you to produce parts with high accuracy and repeatability.

- Possibility of producing moldings - along with metal perforation, this equipment can also perform molding operations (forming, beading, countersinking, stiffeners, etc.)