Powder coating of metal

The company LLC Production Complex "Svet Shakhtyora" offers powder coating of metal. Custom metal painting for industry, companies and individuals, which we carry out efficiently, quickly and using modern high-performance equipment. In our company you can order painting or a full range of metal processing services.

The selection of colors is made according to the RAL catalog. In our work we use powder paints from well-known European manufacturers.

We use modern equipment for applying powder paint and a polymerization oven with dimensions of 3.0x2.1x1.2m.

Technology Features:

Powder painting of metal products in our company is carried out in three stages:

1. Surface preparation. Stubborn stains, rust, scale or paint can be removed using shot blasting and laser cleaning. To protect the product from corrosion, degreasing, phosphating and applying a zinc-containing primer are carried out.

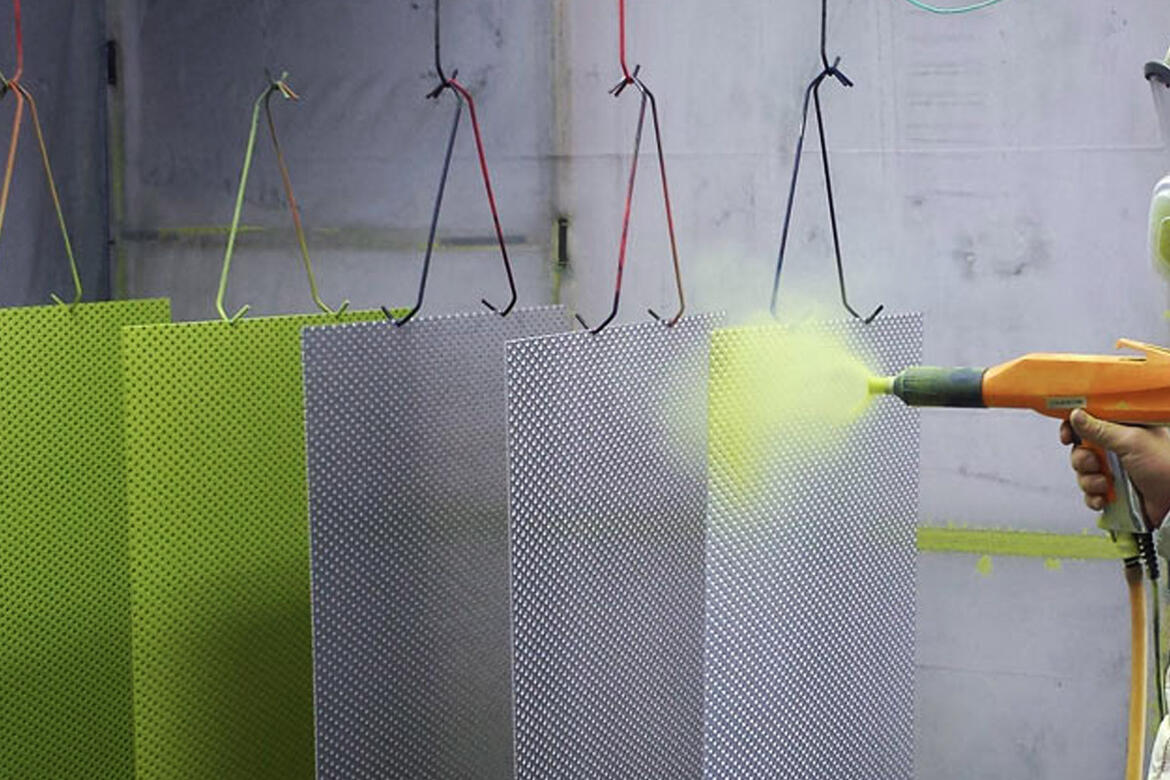

2. Applying paint. The parts are placed in the paint booth. The paint is sprayed under the influence of an electrostatic field - the powder evenly covers the parts and penetrates into hard-to-reach places.

3. Polymerization. The products are moved into a polymerization oven measuring 3000x2100x1200 and kept at temperatures from 140 to 220°C. Baking time – 15-30 minutes.

Advantages of the technology:

- Painting forms an impact-resistant anti-corrosion coating that withstands the temperature range from -60 to + 150C and ensures stability, strength and durability.

- The choice of colors and textures is practically unlimited. It is possible to choose any shades and textures: gold or silver metallic, imitations of bronze, copper, stone, etc.

- Paints are supplied in a finished form, which excludes expensive viscosity control and toning procedures.

- No solvents - savings on the cost of paint.

- Low level of waste. Almost 100% of the paint is transferred to the work surface

- About 95% of the paint collected in the process can be reused

- No flammable or toxic liquid solvents are used

- Absence of harmful organic compounds

- No chemical smell

- Fire Security

Limitations of technology:

- Dyeing is possible only in production conditions with the use of special equipment;

- Coloring is not possible, only ready-made paints from the manufacturer are used;

- It is difficult to eliminate local defects, it is usually necessary to completely repaint the product;

- only products made of heat-resistant materials can be painted (polymerization temperature 140-220°C);

- The dimensions of the products to be painted are limited by the overall dimensions of the polymerization furnace 3000x2100x1200 mm